Angle Seat Piston Globe Valve - Y Pattern

Angle seat piston globe valves or Y pattern globe valves are best suited for most applications if manufactured from Stainless Steel as this is a strong chemical and wear resistant material especially when combined with PTFE sealing. Some better manufacturers use a stainless pneumatic air actuator (pneumatic head) which prevent heat, wear and maintenance damage and vastly increases the valve service life.

The combination of correctly chosen materials of construction has generated one of the best quality compact high performance reliable pneumatically operated angle seat piston globe valves in the market today, avoiding the pitfalls cheap Plastic actuators or bronze bodied valves these more robust series all stainless valves outperform outlast and yet still remain highly competitive fluid or gaseous media control solution in the market today.

Typically all Angle Seat Piston Valves will have Anti-Water Hammer Design when flow is from under the seat and the better ones will have self-cleaning valve seats, higher Kv flow values and pressure ratings.

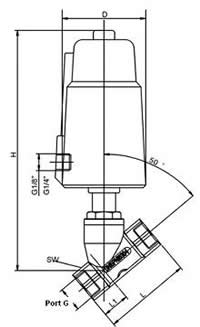

ANGLE SEAT PISTON GLOBE VALVE

- 316 Stainless Steel

- 3/8 - 3 BSP

- 2 WAY AIR DIRECT ACTING

- 0 to 16 Bar

- Type ASPVSS

- Media: air – water – oil - steam

- Pressure range: 0 to 16 bar Max

- Media temp: -10° to +200° C

- Ambient temp:+5° to +60°

- Media viscosity: 600 centistokes max

- Mounting: any position

- Pilot Media: air – water – gas

- Pilot Pressure: 5 to 8 Bar

| Ø Port BSP | Function | Ø Orifice (mm) | Flow | Pressure (bar) Max | Actuator (mm) | Part Number | ||

|---|---|---|---|---|---|---|---|---|

| Kv Ltr/Min | Min | 2 to 1 Over Seat | 1 to 2 Under seat | |||||

| 3/8 | N/Closed | 10 | 75 | 0 | 16 | 8 | 40 | ASPV10SS |

| 1/2 | N/Closed | 15 | 90 | 0 | 16 | 8 | 40 | ASPV15SS |

| 3/4 | N/Closed | 20 | 167 | 0 | 16 | 8 | 50 | ASPV20SS |

| 1 | N/Closed | 25 | 253 | 0 | 16 | 8 | 50 | ASPV25SS |

| 11/4 | N/Closed | 32 | 383 | 0 | 16 | 8 | 63 | ASPV32SS |

| 11/2 | N/Closed | 40 | 683 | 0 | 16 | 8 | 80 | ASPV40SS |

| 2 | N/Closed | 50 | 1183 | 0 | 16 | 8 | 80 | ASPV50SS |

| 21/2 | N/Closed | 65 | 1800 | 0 | 16 | 16 | 100 | ASPV65SS |

| 3 | Double Acting | 80 | 2667 | 0 | 16 | 16 | 125 | ASPV80SS |

Options

- Visual Position Indicator (Except 3" Double acting)

- Anti water hammer flow under seat (0 to 8 Bar)

- Normally Open Version (Except ASPV80SS which is double acting)

- Open Position Proximity Switch (Black Synthetic Actuator only)

- Double Acting, 3 Way, Flanged and other custom made options available upon request

Construction

- Body, Tube, Piston and internal parts: AISI316 (CF8M) Stainless Steel.

- Actuator: AISI304 stainless steel (Rotation 360°)

- Seals and gaskets: Valve Body- PTFE.

- Pneumatic Actuator - FKM.

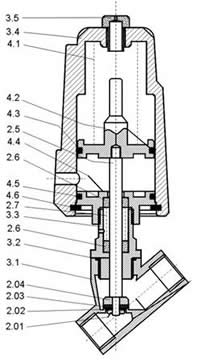

- 2.01 Bolt

- 2.02 Orifice Plate Seal

- 2.03 Disc Seal

- 2.04 Disc

- 2.5 Steam

- 2.6 V Seal

- 2.7 Spring

- 3.1 Body

- 3.2 Seal Ring

- 3.3 Screw connector

- 3.4 Cylinder

- 3.5 Cover

- 4.1 Spring

- 4.2 Piston

- 4.3 O ring

- 4.4 Bonnet

- 4.5 O Ring

- 4.6 Bearing Ring

- Strong Long Life 316 Stainless Steel Angle Seat Valve Actuator, Body + Internal Parts PTFE seals as standard.

- High temperature steam rated +200 Centigrade

- Stock Angle Seat Piston Valve sizes 3/8" BSP to 3" BSP with Anti Water Hammer Design.

- Ideal for Aggressive and demanding applications where quality of product and delivery time are essential.

Continued focus on quality and reliability through volume / stock purchasing as offset most of the additional costs for an all stainless steel angle seat piston valve design making these valves a cost effective solution even for general purpose water and high cycle aggressive or corrosive, glutinous, chemical or steam application.

Sizes typically available 3/8, 1/2, 3/4, 1, 11/4, 11/2 and 2" BSP or NPT thread, with 21/2 and 3" BSP and with options for flanged pneumatically operated angle seat piston valves, 3 Way Angle Seat Piston Valves, Angle Seat Piston Valves with Open Proximity Switches, Normally Open and Double Acting Angle Seat Piston Valves, Welding and Tri Clamp connections also available quickly and cost effectively. Pneumatic Angle Seat Piston Valve is a pneumatically-controlled valve with a piston actuator providing linear actuation to lift a seal off its seat.

The seat is set at an angle to provide the maximum possible flow when unseated. Angle seat piston valves are particularly suited to applications where high temperatures, large flow rates, aggressive and viscous media are required, such as steam, water, heavy oil and Acids or Alkali’s . When used in reverse the angle seat piston valve will eliminate water hammer when operated.

ASPVSS BSP Series Pneumatic angle seat piston valves application: water, air, steam, gas, natural gas, chemicals, petroleum products, food, sterilisation, water treatment, dyeing cleaning plant, aggressive liquids, vacuum application, oil, petrol, alcohol, hydraulic liquids, salt solutions, acids,organic solvent. All body is AISI316 Stainless Steel, high flow rate, high quality, compact, suitable vacuum application, normally open and normally closed position options.

ASPVSSF Flanged Series ,pneumatic actuated angle seat piston valve application: water, air, steam, gas, natural gas, chemicals, petroleum products, food, sterilisation, water treatment, dyeing cleaning plant, aggressive liquids, vacuum application, oil, petrol, alcohol, hydraulic liquids, salt solutions, acids,organic solvent. All body is AISI316 Stainless Steel, high flow rate, high quality, compact, suitable vacuum application, normally open and normally closed position options.