Brass Solenoid Valves 2/2 Way Normally Closed Direct Acting

Direct Acting also known as poppet type solenoid valves will operate at zero pressure, they are a compact or miniature cost effective design. The magnetic core or armature is directly responsible for the ON OFF or open closed control of the solenoid valve as this rests over the orifice or flow path of the solenoid valve. Available in 2/2-way and 3/2-way versions with pressure ratings up to 200 Bar but will suffer a reduced flow

PU220AR

- Pressure: 0 to 10 bar

- Port: 1/8,1/4 or 3/8" BSP or NPT thread

- Seal: NBR,FKM or EPDM

- Media: gas, fluid, air, water, vacuum, light oil and non aggressive media

AD6000

- Pressure: 0 to 150 bar

- Port: 1/8" BSP or NPT thread

- Seal: NBR,FKM or EPDM

- Media: gas, fluid, air, water, vacuum, light oil and non aggressive media

AD8000

- Pressure: 0 to 150 bar

- Port: 1/4" BSP or NPT thread

- Seal: NBR,FKM or EPDM

- Media: gas, fluid, air, water, vacuum, light oil and non aggressive media

CS AD Series

miniature series: AD6, AD8, AD10, AD12

- Function: 2/2 way normally closed

- Operation: direct acting

- Pressure: 0 to 10 bar

- Body: brass

- Port: 1/8",1/4",3/8" and 1/2" BSP or NPT thread

- Seal: NBR,FKM,PTFE,Silicone or EPDM

- Media: gas,fluid,water,air,vacuum,light oil and non aggressive media

PU220A \Series

- Function: 2/2 way normally closed

- Operation: assisted lift diaphragm

- Pressure: 0 to 16 bar

- Body: brass

- Port: 3/8",1/2",3/4" or 1" BSP or NPT thread

- Seal: NBR,FKM or EPDM

- Media: gases,fluid,air,water,vacuum,light oil and sprinkler fire systems

850 Series

- Function: 2/2 Normally Closed

- Operation: Direct Acting

- Pressure: 0 to 16 Bar

- Port: 3/8, 1/2, 3/4, 1, 11/4, 11/2 or 2" BSP or NPT thread

- Body: Red Brass

- Seal: NBR, FKM, PTFE or EPDM

- Media: Air, Gas, Fluid, Water, Vacuum, Light Oil and non aggressive

- Option: ATEX EExmIIT4

RSG 270 Range

- Function: 2/2 normally closed

- Operation: direct acting

- Pressure: 0 to 40 bar

- Body: brass or stainless steel

- Port: 1/4",3/8",1/2",3/4",1",11/4",11/2 or 2" BSP or NPT thread

- Seal: FKM,PTFE,NBR,EPDM

- Media: gas,fluid,air,water,oil and non aggressive media

RSG 271 Range

- Function: 2/2 normally closed

- Operation: direct acting

- Pressure: 0 to 64 bar

- Body: brass or 304 and 316 stainless steel

- Port: 1/4",3/8",1/2",3/4",1",11/4",11/2" or 2" BSP, NPT thread or flange

- Seal: FKM,PTFE,NBR or EPDM

- Media: gas,fluid,air,water,oil and non aggressive media

Brass Solenoid Valves 2/2 Way Normally Closed Servo / Pressure Assisted

Servo Assisted also known as pilot operated, floating diaphragm, floating piston and pilot assisted solenoid valves. These solenoid valves require a minimum pressure difference to operate i.e. a higher inlet pressure than outlet pressure (minimum pressure difference) which is typically 0.2 to 0.5 bar which is controlled via an internal pilot circuit to operate the open and close function of the solenoid valve. Brass pressure assisted solenoid valves are available in 2/2 way normally closed and normally open function with pressure ratings up to 200 Bar and typically offer good flow rates. Ideally suited for medium to high pressure applications and open to atmosphere general purpose systems.

Normally Closed

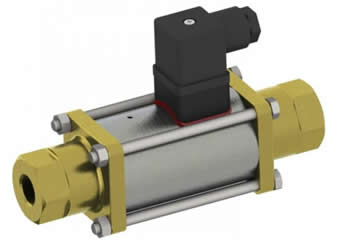

CS Fluid SAP

- Function: 2/2 way normally closed

- Operation: pressure assisted piston

- Pressure: 0 to 100 bar

- Body: brass

- Port: 1/8",1/4" or 3/8" BSP or NPT thread

- Seal: PTFE

- Media: gas,air,fluid,water,light oil and non aggressive media

PU225A Series

- Function: 2/2 Normally Closed

- Operation: pressure servo assisted diaphragm

- Pressure: 0.5 to 10 bar differential,15 bar maximum working

- Port: 3/8",1/2",3/4",1",11/4",11/2",2",21/2" and 3" BSP thread

- Body: Brass

- Seal: NBR,FKM or EPDM

- Media: gas,air,fluid,water,light oil and non aggressive media

PU225H Range

- Function: 2/2 normally closed

- Operation: pressure servo assisted diaphragm

- Pressure: 0.5 to 25 bar

- Body: brass or stainless steel

- Port: 3/8,1/2,3/4 or 1" BSP or NPT thread

- Seal: nylon reinforced NBR,EPDM or FKM

- Media: gas,air,fluid,water,light oil and non aggressive media

PU225X Range

- Function: 2/2 normally closed

- Operation: pressure servo assisted piston

- Pressure: 0.5 to 50 bar (test pressure 75 bar)

- Body: brass

- Port: 3/8,1/2,3/4 or 1" BSP or NPT thread

- Seal: PTFE

- Media: gas,air,fluid,water,light oil and non aggressive media

- ATEX option available.

Normally Closed

Shako SA Range

- Function: 2/2 way normally closed

- Operation: pressure servo assisted piston

- Pressure: 0.5 to 20 bar air water or 12 bar steam (+200°C maximum)

- Body: brass

- SAH SAHH SAHHH: Stainless steel piston

- Port: 1/8", 1/4", 3/8", 1/2", 3/4", 1", 11/4", 11/2" and 2" BSP or NPT

- Seal: PTFE

- Media: gas,air,fluid,water,light oil and non aggressive media

Shako SAH Range

- Function: 2/2 way normally closed

- Operation: pressure servo assisted piston

- Pressure: 0.5 to 40 bar

- Body: brass

- Piston: Stainless steel

- Port: 3/8",1/2",3/4",1",11/4",11/2" or 2" BSP or NPT thread

- Seal: PTFE

- Media: gas,air,fluid,water,light oil and non aggressive media

Shako SAHH Range

- Function: 2/2 way normally closed

- Operation: pressure servo assisted piston

- Pressure: 0.5 to 80 bar air water or 12 bar steam

- Body: brass

- Piston: Stainless steel

- Port: 3/8",1/2",3/4",1",11/4",11/2" and 2" BSP or NPT thread

- Seal: PTFE

- Media: gas,air,fluid,water,light oil and non aggressive media

Z Tide BFE-D

- Function: 2/2 Normally Closed

- Operation: pressure servo assisted piston

- Pressure: 0.3 to 16 Bar

- Port: DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250 and DN300 flange

- Body: ductile iron with epoxy coating

- Seal: NBR,FKM or EPDM

- Media: gas,air,fluid,water,light oil and non aggressive media

Assisted Lift

Assisted Lift also known as Hung Diaphragm or Kick Pilot Solenoid Valves. These solenoid valves will operate from zero pressure differential offering good flow similar to a servo pressure assisted solenoid valves, however the diaphragm or piston is mechanically attached to the solenoid armature thus ensuring the valve opens fully regardless of pressure difference. These are ideally suited to closed loop and low pressure gravity fed systems where high flow is required combined with low differential pressures but are typically more expensive than servo assisted solenoid valves. These assisted operation brass solenoid valves are a reliable choice when minimum pressures are not known or if users what to ensure brass solenoid valve operation at all times.

Normally Open

Shako NOPU225

- Function: 2/2 way normally open

- Operation: pressure servo assisted diaphragm

- Pressure: 0.5 to 10 bar differential, 15 bar maximum working

- Body: brass

- Port: 3/8",1/2",3/4",1",11/4",11/2",2",2/12" and 3" BSP thread

- Seal: NBR,FKM or EPDM

- Media: gas,air,fluid,water,light oil and non aggressive media

Shako NOPU225H

- Function: 2/2 way normally closed

- Operation: pressure servo assisted diaphragm

- Pressure: 0.5 to 22 bar

- Body: brass

- Port: 3/8",1/2",3/4" and 1" BSP or NPT thread

- Seal: nylon reinforced EPDM

- Media: gas,air,fluid,water,light oil and non aggressive media.

CS Fluid NOHPV

- Function: 2/2 way normally closed

- Operation: pressure servo assisted diaphragm

- Pressure: 0.5 to 50 bar

- Body: brass

- Port: 3/8" or 1/2" BSP or NPT thread

- Seal: EPDM,FKM,Silicone or NBR

- Media: gas,air,fluid,water,light oil and non aggressive media

Pro UNI-D

- Function: 2/2 Normally Open

- Operation: assisted close hung diaphragm

- Pressure: 0 to 7 bar differential, 10 bar maximum working

- Port: 3/8",1/2",3/4"1",11/4",11/2" or 2" BSP or NPT thread

- Body: brass

- Seal: NBR,FKM or Silicone

- Media: gas,air,fluid,water,light oil and vacuum