ATEX Certified Explosion Proof Solenoid Valves for Hazardous Gas and Dust Areas.

ATEX encapsulated EEx M II T4 solenoid valves for Zone 21 and 22, ATEX EEx d IIC T4 and T6 Explosion and flame proof solenoid valves and a small range of ATEX EEx ia IIC T4 and T6 intrinsically safe solenoid valves in most voltages, pressures, sizes and materials of construction.

| Zone | Category | | Presence of explosion atmospheres |

| Group II Equipment |

| Zone 0 | Category 1 | G | Continuous, Frequent |

| Zone 20 | Category 1 | D | for long periods |

| Zone 1 | Category 2 | G | Intermittent |

| Zone 21 | Category 2 | D | in normal operation Likely |

| Zone 2 | Category 3 | G | Occasional or for short periods. |

| Zone 22 | Category 3 | D | Never in normal operation |

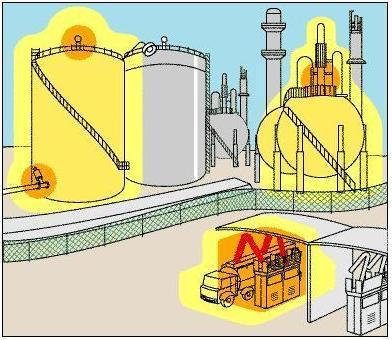

Zones

Hazardous areas for Group II are further divided into Zones, these Zones relate to the predicted occurrence of when an Explosive Atmosphere may be present in the area. These Zones are defined as being:

| Colour | Zone | Presence of Gas |

| Red | 0 | Continuously present (During long periods) |

| Orange | 1 | Not Likely to be present (Regular service) |

| Yellow | 2 | Accidentally present (short time service never in regular service) |

| Colour | Zone | Presence of Dust |

| Red | 20 | Continuously present (During long periods) |

| Orange | 21 | Not Likely to be present (Regular service) |

| Yellow | 22 | Accidentally present (short time service never in regular service) |

Types of ATEX Explosion Proof Protection Available from Connexion Developments Ltd

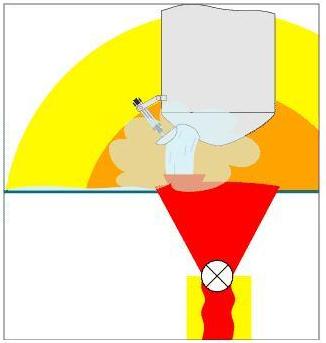

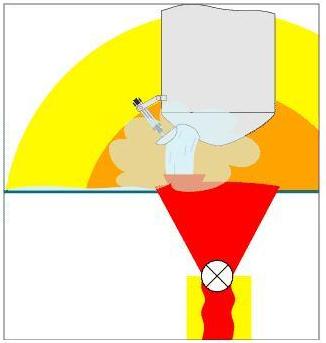

| Protection Symbol | 0 | 20 | 1 | 21 | 2 | 22 | Description | Drawing |

| EexmIIT4 "m" Cenelec EN50028 | | | X | X | X | X | Encapsulation. Refers to a special casing in which the parts of an electrical apparatus which could ignite an explosive atmosphere by either sparking or heating are encapsulated in a compound in such a way that this explosive atmosphere cannot be ignited |  |

| EexiaIICT6 "ia" Cenelec EN50020/39 | X | X | X | X | X | X | Intrinsically Safe. Refers to a circuit in which neither sparks or temperature can ignite an explosive atmosphere. If generated under the service conditions specified by the standard regulations (Normal and faulty operating conditions). |  |

| EexdIICT2 - 6 "d" Cenelec EN50018 | | | X | X | X | X | Flameproof enclosure. Refers to an electrical apparatus whose explosive parts are enclosed in an explosion proof casing. This casing will resist the pressure generated by the internal explosion or an explosive mixture and will prevent the explosion from penetrating to the ambient explosive atmosphere. |  |

Temperature Classes

Group 1

Temperature <150 C or <450 C according to coal dust accumulation on equipment

Group II

| Class for Gas (G) | Max surface temperature |

| T1 | 450 °C |

| T2 | 300 °C |

| T3 | 200 °C |

| T4 | 135 °C |

| T5 | 100 °C |

| T6 | 85 °C |

Ignition Temperature for Dusts.

The dust ignition temperature depends on its consistency and its nature. The ignition temperatures for various types of dust are available from reference tables.

| | Ignition Temperature |

| Dusts | Clouds | 5mm Layer |

| Aluminium | 560°C | >450°C |

| Charcoal | 520°C | 320°C |

| Coal Dust (Lignite) | 380°C | 225°C |

| Cocoa | 590°C | 250°C |

| Coffee Grounds | 580°C | 290°C |

| Corn | 530°C | 460°C |

| Methyl cellulose | 420°C | 320°C |

| Paper Fibre | 570°C | 335°C |

| Phenolic Resin | 530°C | >450°C |

| Polyethylene | 440°C | melts |

| PVC | 700°C | >450°C |

| Sugar | 490°C | 460°C |

| Soot | 810°C | 570°C |

| Starch | 460°C | 435°C |

| Toner | 520°C | melts |

| Wheat | 510°C | 300°C |

Ignition Temperature for Fuels & Chemicals.

| Fuel or Chemical | Temperature |

| Acetaldehyde | 175°C | 347°F |

| Acetone | 465°C | 869°F |

| Acetylene | 305°C | 581°F |

| Anthracite - glow point | 600°C | 1112°F |

| Benzene | 560°C | 1040°F |

| Bituminous coal - glow point | 454°C | 850°F |

| Butane | 420°C | 788°F |

| Carbon | 700°C | 1292°F |

| Carbon - bi sulfide | 149°C | 300°F |

| Carbon monoxide | 609°C | 1128°F |

| Charcoal | 349°C | 660°F |

| Coal-tar oil | 580°C | 1076°F |

| Coke | 700°C | 1292°F |

| Cyclohexane | 245°C | 473°F |

| Diethyl ether | 160°C | 320°F |

| Ethane | 515°C | 859°F |

| Ethylene | 490°C | 914°F |

| Ethyl Alcohol | 365°C | 689°F |

| Fuel Oil No.1 | 210°C | 410°F |

| Fuel Oil No.2 | 256°C | 494°F |

| Fuel Oil No.4 | 262°C | 505°F |

| Heavy hydrocarbons | 750°C | 1382°F |

| Hydrogen | 500°C | 932°F |

| Gas oil | 336°C | 637°F |

| Gasoline | 280°C | 536°F |

| Gun Cotton | 221°C | 430°F |

| Kerosene | 295°C | 563°F |

| Isobutane | 462°C | 864°F |

| Isobutene | 465°C | 869°F |

| Isooctane | 447°C | 837°F |

| Isopentane | 420°C | 788°F |

| Isopropyl Alcohol | 399°C | 750°F |

| Light gas | 600°C | 1112°F |

| Light hydrocarbons | 650°C | 1202°F |

| Lignite - glow point | 526°C | 979°F |

| Methane (Natural Gas) | 580°C | 1076°F |

| Methyl Alcohol | 385°C | 725°F |

| Naphtha | 550°C | 1022°F |

| Neohexane | 425°C | 797°F |

| Neopentane | 450°C | 842°F |

| Nitro-glycerine | 254°C | 490°F |

| n-Butane | 405°C | 761°F |

| n-Heptane | 215°C | 419°F |

| n-Hexane | 225°C | 437°F |

| n-Octane | 220°C | 428°F |

| n-Pentane | 260°C | 500°F |

| n-Pentene | 298°C | 569°F |

| Oak Wood - dry | 482°C | 900°F |

| Peat | 227°C | 440°F |

| Petroleum | 400°C | 752°F |

| Pine Wood - dry | 427°C | 800°F |

| Phosphorous, amorphous | 260°C | 500°F |

| Phosphorous, transparent | 49°C | 120°F |

| Production gas | 750°C | 1382°F |

| Propane | 480°C | 842°F |

| Propylene | 458°C | 856°F |

| p-Xylene | 530°C | 986°F |

| Rifle Powder | 288°C | 550°F |

| Toluene | 530°C | 849°F |

| Semi anthracite coal | 400°C | 752°F |

| Semi bituminous coal - glow point | 527°C | 980°F |

| Styrene | 490°C | 914°F |

| Sulphur | 243°C | 470°F |

| Wood | 300°C | 572°F |

| Xylene | 463°C | 867°F |