Solenoid Valve Installation and Maintenance Instructions.

Before mounting the valve it is essential to check that the solenoid valve model, the voltage (Volt) and the frequency (Hz) correspond to the characteristics required.

Mechanical

- Assembly of the solenoid valve must correspond with the flow direction indicated with an arrow on the valve body.

- If the valves are provided with caps for protecting the connections, make sure they are removed before assembly.

- Care should be taken to prevent foreign bodies from entering the valve during the assembly phase, e.g. material chips, dirt or particles of insulating material such as PTFE tape from the "external thread" connections.

- Although the valve can be used in any position, the inverted position is not advised since possible impurities could become blocked inside the tube causing malfunctioning.

- When installing the valve make sure that the position and surrounding space are sufficient to allow for possible future maintenance or replacement of the coil.

- Never use part of the tube or the coil itself as a lever during the tightening phase: this could cause irreparable damage to the valve.

- In those installations where impurities, slag or deposits of various types may infiltrate the fluid, it is advisable to mount a filter upstream of the valve

- In case of solenoid valves with holes drilled for supports, use must be made exclusively of these without modifying the holes or anything else on the valve body.

- For solenoid valves with connections to be welded, please refer to Working Temperature below.

Electrical Connections

- Before connecting the coil to the supply system, make sure that the characteristics conform to the supply voltage.

- Where applicable the earth terminal must be connected.

- The coil should not be energised before being installed on the valve since this could cause it to burn out.

- Rotate the coil to the most suitable position, loosening and subsequently tightening the upper nut.

Working Temperature

- It is normal for the coil temperature to increase during operation; irregular overheating will cause smoke and smell of burning. In this case the power supply must be immediately isolated.

- Care should be taken not to install the valve near a source of heat or in environments where there could be a disruption to the dissipation of heat produced by the coil.

- For special conditions, e.g. high temperatures or particular safety regulations please consult our catalogue or our Technical Office.

- Particular attention should be paid to the temperatures when installing valves with welded connections.

- When carrying out welding between the valve connection and the pipe system, it is necessary to dismantle the coil and check that the temperature of the valve body does not exceed values of 100°C - 150°C (200°F -300°F). The flame should be regulated so that it does not come into contact with the valve. It is advisable to cool the valve body by wrapping it in a wet cloth. Should it be impossible to carry out these precautions, we suggested dismantling the parts inside the valve.

Maintenance

- After disconnecting the supply voltage and discharging the pressure, carry out inspection of the valve

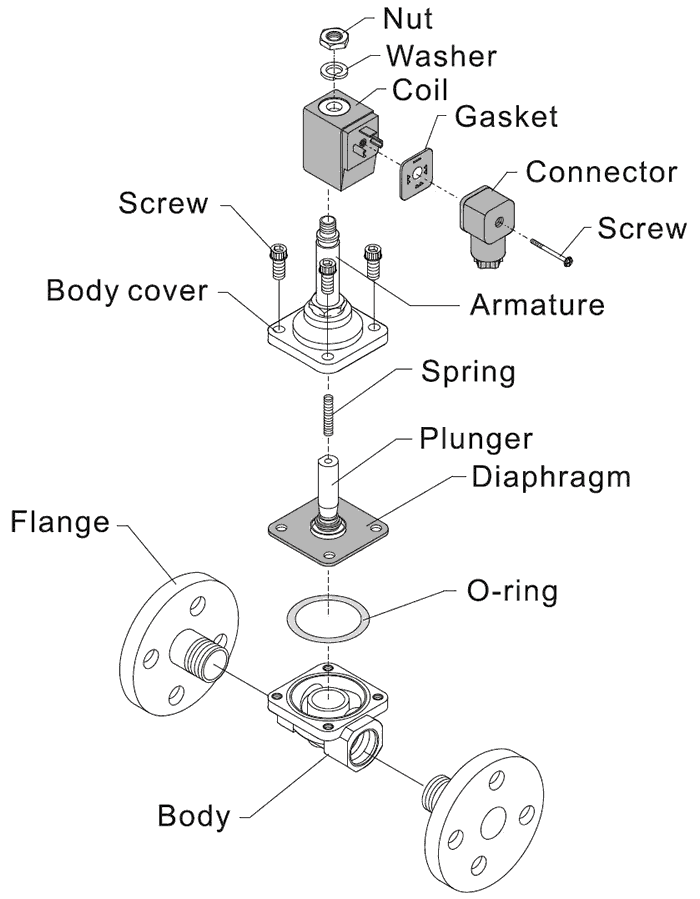

- Clean and inspect all the internal parts and replace them if necessary with type original spare parts available, as indicated in the catalogue.

- Remount all the parts, making up the solenoid valve with care, paying great attention to the correct position of each part and protecting the sealing surfaces.

- Check for tightness and correct operation.

These general instructions give an approximate idea of the correct use of the solenoid valves but cannot in any way be considered as a substitute for the catalogue giving all the characteristics of every solenoid valve. Please consult this volume or our technical office for every new installation.

Valve Material

Body

| Material | Material Reference | Features |

|---|---|---|

| Brass | 2.0402 | Widely used, not suitable for corrosive medium |

| S.S.304 | AISI 304 | Mainly used for slightly corrosive medium. |

| S.S.3116 | AISI 316 | Mainly used for very corrosive medium. |

| Aluminium alloy | A1Si8 Cu 3 | Mainly used for neutral medium. |

Seal

| Material | Temperature | Features |

|---|---|---|

| NBR | -10°C —+80°C | Suitable for most neutral medium, such as air, water and so on. |

| FPM | -20°C —+180°C | Suitable for acid, alkali and oil medium, not suitable for hot water or steam. |

| PTFE | -180°C —+200°C | Suitable for corrosive medium |

Instructions for Installation and Application of Pneumatic Valves

- Make sure that the model and parameter of the pneumatic valve are in accordance with the site installation and technical requirement.

- Make sure the valve cylinder and position indicator are undamaged.

- Clean the inside of the pipe of the pneumatic valve of any debris please also install the filter valve in the front of the valve pipe.

- Install as per direction of the arrow on the valve body; Connect the valve mouth to the pipe and make sure the connection is well sealed.

- If the pneumatic valves are equipped with electric valve, please insure that the connection is well sealed.

- Avoid heating the seals of the pneumatic valve if welding.

Notices of installation of pneumatic valve and electric valve

- Keep the fluid and gas clean to prevent blocking electric valve or piston.

- Don’t touch the coil while solenoid valve works and gets hot.

- Don’t take off the coil while the solenoid coil is energised as it will burn out.

- Don’t hit the coil, solenoid pipe and the connecting part to cause any damage.

- Don’t cover the coil of the solenoid valve to prevent over-heating and burning out.

- The actual supply voltage of the solenoid valve should not exceed the tolerance.

- The working pressure, working temperature, viscosity of the medium should not exceed the specified scope.

Maintenance

- Before disassembling the pneumatic valve, drain the fluid inside the cylinder and the media from inside the valve. Thoroughly clean the media if it is inflammable, potentially explosive or high temperature or high pressure or it is toxic or corrosive.

- Step of Disassemble pneumatic valve:

- Disassembly of cylinder: Take off the locking ring, lift the cylinder and take it out. The piston, spring, position indicator and stem are visible.

- Disassembly of valve body: Loosen with spanner at the end of the valve cover.

- Disassembly of seals: Disassemble the valve body, and the seals are at the end of the stem; remove the screw that fastens the seals.

- Then assemble the valve step by step refer to the step of disassembling.

- The parts such as seals, locking ring and spring should be assembled correctly. Tighten the connection properly, do not damage the seals or valve seat.

- The maintained valve must pass the pressure and leakage test, and then it can be put into use.